SINGLE GIRDER E.O.T. CRANE

SINGLE GIRDER E.O.T. CRANE

The Single Girder E.O.T. Crane is a reliable and cost-effective material handling solution designed for light to medium-duty lifting in industrial environments. Ideal for workshops, warehouses, fabrication units, and assembly lines, this crane features a single bridge girder with a hoist that travels along the bottom flange. Its compact design, easy installation, and low maintenance make it a preferred choice for businesses looking to optimize space and operational efficiency.

With lifting capacities typically up to 20 tons, the single girder E.O.T. crane offers smooth performance, precise control, and essential safety features, making it a popular choice across various sectors in India.

Single Girder E.O.T. (Electric Overhead Traveling) Crane

A Single Girder E.O.T. (Electric Overhead Traveling) Crane is a highly efficient and cost-effective material handling system used across various industries for lifting and moving medium-duty loads. Known for its lightweight design, ease of operation, and versatility, the single girder EOT crane is ideal for workshops, warehouses, small manufacturing units, and assembly lines.

In this comprehensive guide, we’ll explore everything you need to know about single girder E.O.T. cranes, including their features, advantages, typical specifications, applications across industries, and tips for choosing the right crane for your needs.

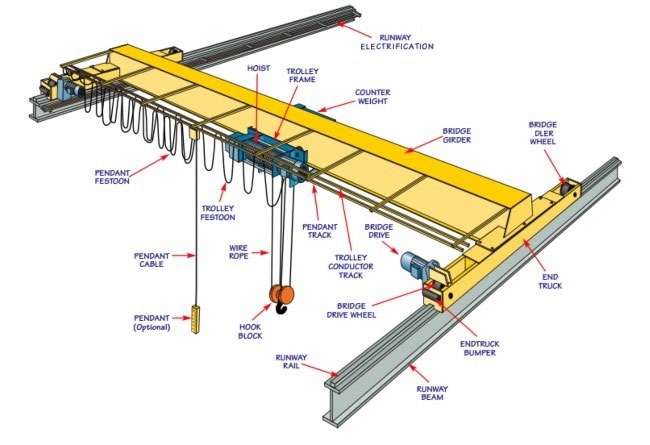

What is a Single Girder E.O.T. Crane?

A Single Girder E.O.T. Crane features a single bridge girder supported on end carriages. A wire rope hoist or chain hoist is mounted on a trolley that runs along the bottom flange of the girder. The entire crane moves over runway beams that are fixed along the building’s length.

This type of crane is best suited for lighter duty cycles and lifting capacities, generally up to 20 tons. Due to its simplified structure, a single girder crane is not only affordable but also requires less installation space and maintenance.

Key Features of Single Girder E.O.T. Cranes

- Lightweight and Compact Design: Reduces space requirements and structure load.

- Cost-Effective: Lower material usage and simple construction.

- Ease of Installation: Modular design allows faster setup.

- Customizable: Designed to match specific span, height, and capacity needs.

- Efficient Operation: Easy controls via pendant, radio, or remote.

- Low Maintenance: Fewer parts and reliable build reduce servicing costs.

- Safe Operation: Equipped with limit switches, overload protection, and emergency brakes.

Benefits of Using Single Girder E.O.T. Cranes

1. Economical Material Handling

Reliable lifting solution with lower installation and operational cost.

2. Ideal for Low to Medium Loads

Supports lifting from 500 kg to 20 tons, perfect for general industry needs.

3. Improved Floor Space Utilization

Compact under-slung design makes it ideal for space-constrained facilities.

4. Flexible Control Options

Operated using pendant controls, remotes, or cabin depending on application.

5. Versatile Mounting Options

Mounts on floor gantries or ceiling beams based on available space.

Applications of Single Girder E.O.T. Cranes in India

- Manufacturing Units: Used for lifting tools, dies, and assemblies.

- Warehouses and Logistics: Helps move and organize goods efficiently.

- Engineering Workshops: Handles machine parts and heavy metals.

- Construction Sites: Moves steel bars, prefabs, and building materials.

- Power and Energy Sector: Ideal for handling transformers and turbines.

- Textile and Paper Mills: Lifts bales, rolls, and other bulk materials.

Technical Specifications (Typical Range)

| Parameter | Range |

|---|---|

| Lifting Capacity | 500 kg to 20 Tons |

| Span | Up to 25 meters |

| Lifting Height | Up to 15 meters |

| Hoisting Speed | 3 to 10 m/min (variable) |

| Cross Travel Speed | 10 to 20 m/min |

| Long Travel Speed | 15 to 30 m/min |

| Control Type | Pendant, Radio Remote |

| Crane Duty Class | M3 to M5 (IS 3177/IS 807) |

| Power Supply | 3 Phase, 415V AC, 50 Hz |

How to Choose the Right Single Girder E.O.T. Crane?

- Load Weight: Define your maximum and average lifting loads.

- Span Length: Match with your building structure.

- Lifting Height: Consider floor clearance and hook reach.

- Duty Cycle: Select appropriate IS class (M3 to M5).

- Control Mode: Choose remote, pendant, or cabin control.

- Environmental Conditions: Consider dust, heat, and humidity factors.

- Installation Area: Floor-mounted or ceiling-mounted options.

- Safety: Ensure essential safety mechanisms are included.

Leading Single Girder E.O.T. Crane Manufacturers in India

- EOT Crane In India

- Mahadev Engineering

- Safex Equipments Pvt. Ltd.

- Reva Industries

- Ambica Engineering Co.

- Shivpra Cranes

- Indef (Hercules Hoists Ltd)

- K2 Cranes & Components

These companies offer reliable, customized single girder EOT cranes for industrial use and provide support across India, Nepal, Bhutan, and neighboring regions.

Maintenance Tips for Single Girder EOT Cranes

- Regular Inspection: Monitor hoists, brakes, and trolleys for wear.

- Lubrication: Ensure proper greasing of moving parts.

- Electrical Testing: Check motors, circuits, and control panels.

- Alignment Check: Align rails and wheels to avoid derailment.

- Load Testing: Conduct periodic load capacity tests.

- Operator Training: Train personnel for safe and correct use.

Conclusion

The Single Girder E.O.T. Crane is a cost-effective, space-efficient, and reliable solution for handling loads in small to medium industrial setups. With its simple design, customizable features, and low maintenance needs, it is widely adopted across India for general material handling purposes.

For industries aiming to increase operational efficiency and workplace safety, investing in a high-quality single girder crane from a reputed manufacturer is a smart and scalable choice.

Our Products